Iron: the extraordinary mineral that made, and makes, history

The international iron market is one of the most important and dynamic among raw materials. Iron is in fact the main component of steel, the most used metal in the world for the production of industrial and consumer goods. Iron is mainly mined in the form of iron ore, a rock that contains a variable percentage of iron oxide. The iron ore is then transformed into cast iron or steel through reduction and refinement processes.

Brief history of the fect

Iron has been used by humans for thousands of years, with the first known use dating back to around 3500 BC. During this time, iron was extracted from meteorites and used to create weapons, tools, and other items. However, it was only much later, during the Iron Age, that iron began to be produced in large quantities. The first well-preserved iron object is a dagger, found in Anatolia, dating back to 2500 BC

The Iron Age is a historical period from around 1200 BC to 500 AD, during which time people began extracting iron from ore and producing it on a larger scale. This was made possible by the development of new technologies, such as the bloom process, which allowed people to smelt iron ore and produce wrought iron.

The blooming process involved heating iron ore in a furnace with charcoal, causing the iron to separate from oxygen and other impurities. The resulting iron was then hammered and bent to remove any remaining impurities and create a workable metal. This process was labor intensive and required a lot of fuel, but allowed for the production of large quantities of iron.

As civilizations developed and technology improved, new methods of producing iron were discovered. For example, the Bessemer process, invented in the 19th century, allowed for the mass production of steel, which is a stronger and more durable form of iron.

Iron minerals

The main minerals used for iron extraction are:

1. Hematite (Fe2O3) : This is the most common iron mineral and is found in large quantities in many parts of the world. It is a black or reddish-brown mineral often found in banded iron formations.

2. Magnetite (Fe3O4) : This mineral is a type of iron oxide that is naturally magnetic, meaning it is attracted to magnets. It is commonly found in igneous and metamorphic rocks and is a significant source of iron.

3. Limonite (FeO(OH)·nH2O): This mineral is a hydrated iron oxide that forms from the erosion of other iron-rich minerals. It is a yellowish-brown mineral often found in clay deposits and is a minor source of iron.

4. Siderite (FeCO3): This mineral is an iron carbonate found in sedimentary rocks, such as limestone and dolomite. It is a less common source of iron than hematite and magnetite, but can still be economically important in some regions.

5. Pyrite (FeS2): While not an iron oxide mineral, pyrite is sometimes included in the list of iron minerals because it can be converted to iron through smelting. It is a brassy yellow mineral with a characteristic cubic crystalline habit that is often found in igneous and metamorphic rocks.

Iron and economy

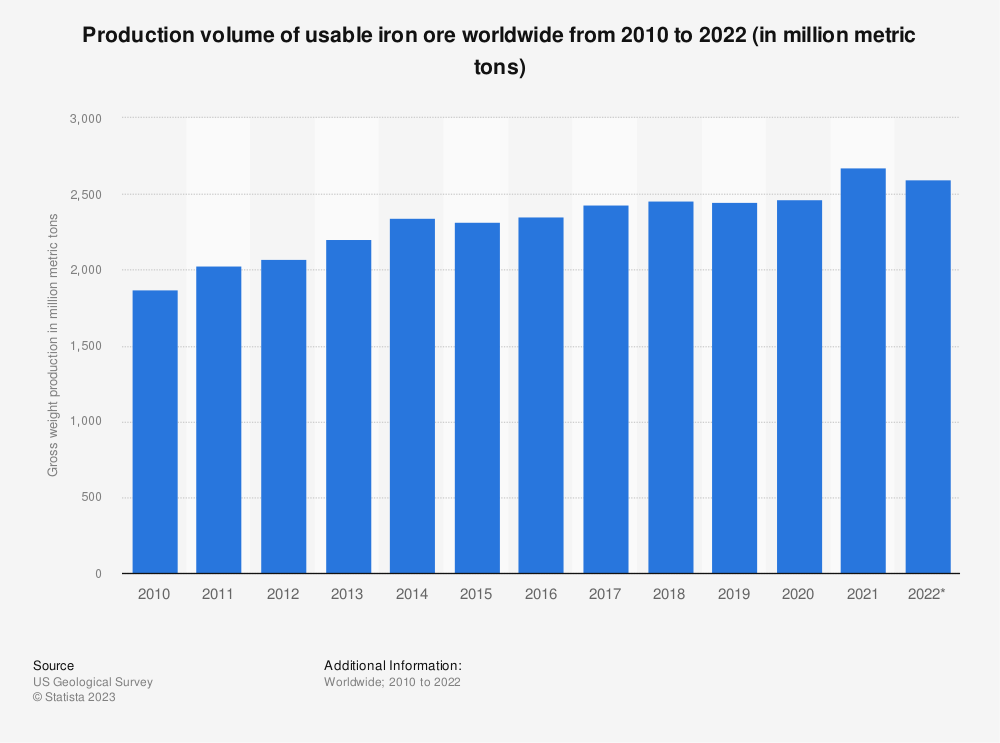

Iron production has been slowly but continuously increasing over the last 10 years to exceed 2,500 million tonnes per year.

The iron ore market is dominated by a few large producers, who hold control of major reserves and trade routes. According to 2020 data, the five largest iron ore producing countries are:

– Australia: with 900 million tonnes, equal to 29.5% of world production;

– Brazil: with 400 million tonnes, equal to 13.1% of world production;

– China: with 340 million tonnes, equal to 11.1% of world production;

– India: with 230 million tonnes, equal to 7.5% of world production;

– Russia: with 100 million tonnes, equal to 3.3% of world production.

The five largest iron ore consuming countries are:

– China: with 1,170 million tonnes, equal to 65.6% of world consumption;

– European Union: with 100 million tonnes, equal to 5.6% of world consumption;

– Japan: with 70 million tonnes, equal to 3.9% of world consumption;

– India: with 60 million tonnes, equal to 3.4% of world consumption;

– United States: with 40 million tons, equal to 2.2% of world consumption.

The main products obtained from iron processing, in various ways, are the following:

- Steel : Steel is the main product derived from iron. It is made by reducing iron ore in blast furnaces and adding alloys and other elements to give it strength and other specific properties. Steel is widely used in construction, automotive, manufacturing, and many other applications.

- Cast Iron : Cast iron is made from molten iron and contains a greater amount of carbon than steel. Cast iron is used to produce foundry parts, pipes, and other applications where compressive strength is important.

- Iron Ingots : Iron ingots represent a form of raw iron produced directly by smelting iron ore. They are used as a raw material for the production of steel and other materials.

- Iron Ore Pellets : Pellets are small globules of iron ore that are used as filler material in steelmaking processes. They are produced by grinding and agglomerating iron ore.

- Rolled products : A variety of rolled products, such as sheets, bars and profiles, are produced from molten steel tongues. These products are used in construction, manufacturing and many other industrial applications.

- Malleable Iron Products : Malleable iron is a special form of cast iron that has greater ductility and strength than traditional cast iron. It is used for the production of complex parts such as hydraulic fittings and other industrial components.

- Iron powders : Iron powders are obtained by grinding iron and are used in applications such as powder metallurgy, magnet manufacturing and the chemical industry.

- Iron Wires and Cables : Iron is used to produce wires and cables that find applications in electronics, electricity, and construction.

- Automotive Components : Many automotive components, such as engines, transmissions, and structural parts, are made using iron or steel.

- Steel Structures : Steel structures, such as bridges, buildings, and towers, are made using steel as the primary material.

The price of iron ore is determined by global supply and demand, as well as factors such as quality, cost of transportation and geopolitical conditions. The main benchmark for the price of iron ore is the Platts Iron Ore Index (IODEX), which reflects the average daily value of spot transactions for ore with a concentration of 62% iron oxide. Other indices are the Metal Bulletin Iron Ore Index (MBIOI) and the China Iron Ore Index (CIOI).

In 2020, the average price of iron ore was around $109 per tonne, up 17% from 2019. The price peaked in December at $164 per tonne, thanks to strong Chinese demand and to the reduced Brazilian supply. In 2021, the price continued to rise, surpassing $200 per ton in May, due to supply shortages and trade tensions between China and Australia. However, some analysts predict a downward correction in the medium term, following an increase in supply and a possible decrease in demand.

The iron market is therefore a strategic and competitive sector, which requires constant investments in technological innovation and environmental sustainability. Future challenges include reducing CO2 emissions associated with steel production, developing new renewable energy sources and adapting to the needs of emerging markets.

Thanks to our Telegram channel you can stay updated on the publication of new Economic Scenarios articles.

The article Iron: the extraordinary mineral that made, and makes, history comes from Scenari Economici .

This is a machine translation of a post published on Scenari Economici at the URL https://scenarieconomici.it/ferro-lo-straordinario-minerale-che-ha-fatto-e-fa-la-storia/ on Mon, 18 Sep 2023 13:17:20 +0000.