The robotic worker arrives in the warehouses

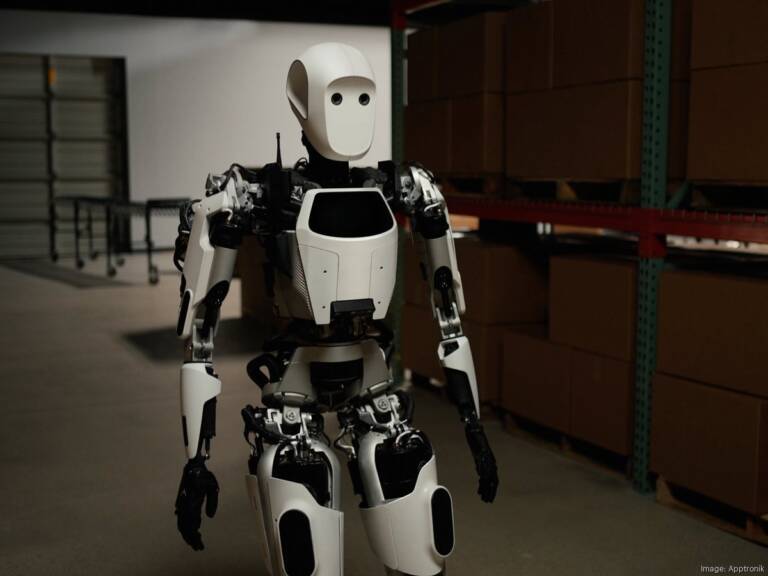

One of the world's largest logistics providers, GXO , which specializes in providing logistics solutions to large industrial groups, has partnered with Apptronik, a robot manufacturer. The collaboration aims to explore the use of Apptronik's Apollo humanoid robot in warehouses.

With the ability to run on swappable batteries, the machine offers the highest operating time of any humanoid robot.

Apollo is moved by a system of muscles similar to human ones, but which, in reality, are electronic actuators. This means that its mobility is maximum and similar to that of man. So the robot is really coming to warehouses and will replace many workers.

Apollo can work directly with people

The robot can carry 25 kg of weight and is 1.80 meters tall. The machine can work safely around and directly with people, thanks to its unique force control architecture and flexible safety zone perimeter. This means that he should not bump into people who come close to him. It can work close to people without danger.

The companies said that together, they are evaluating the robot's overall performance in the lab to further fine-tune Apptronik's AI model, before deploying the technology to a U.S. distribution center once ready.

“We are excited to partner with Apptronik to develop their AI-enabled humanoid robot. Apollo has great potential to add value throughout the distribution center, including the most demanding operational processes,” said Adrian Stoch, Chief Automation Officer at GXO.

“These types of robotics reduce repetitive work and improve safety, freeing employees to focus on higher value-added activities. As we progress on our R&D journey with Apptronik, we will also evaluate its capability for other critical use cases.”

Apollo is already being tested at Mercedes, as you can see in this video.

GXO had already invested heavily in automation

The Humanoid partnership with Apptronik is the second for GXO, a leader in warehouse automation and a first mover in the AI-driven automation space. In 2023, GXO increased total warehouse automation units by approximately 50% compared to the previous year and pioneered a broad range of new hardware and software solutions, which include AI-powered robotics and autonomous vehicles.

“Our mission is to build versatile robots that can get the job done in real-world applications, from large, powerful movements like carrying boxes and crates to small, precise movements like picking individual items or scanning barcodes,” said Jeff Cardenas, co-founder and CEO of Apptronik.

Apptronik's goal is to introduce the next generation of robots that will change the way people live and work, tackling some of our world's greatest challenges.

The company says Apollo will operate in warehouses and manufacturing facilities in the near term, then expand into construction, oil and gas, electronics manufacturing, retail, home delivery, customer service elderly and countless other sectors.

Apollo is the first commercial humanoid robot that is designed for friendly interaction, mass producibility, high payload and safety, according to the company.

The goal for the company is a robot that costs 50 thousand dollars , 46 thousand euros. If the figure seems significant, compare it to the cost of a worker and consider that the variable costs are only energy and a little maintenance.

When the laborer is a robot, who will need human laborers?

At this point the question arises spontaneously: assuming that the CXO – Apollo experiment is successful, this robot will soon work alongside workers to carry out the heaviest jobs. If, as the producers hope, we will have basic workers and robotic labourers, who will need human workers more, with their problems and, above all, with their ability to suffer, or cause, accidents.

The mere fact that a robot that suffers an accident at work does not give rise to criminal liability and has limited financial costs will mean that there will be a tendency towards the replacement of every non-supervisory position, until such time as supervision also may be entrusted to the AI.

At that point, what will the workers do, considering that by eliminating the labourers, i.e. the younger ones, we will begin with the elimination of work right at the base?

Thanks to our Telegram channel you can stay updated on the publication of new Economic Scenarios articles.

The article the robotic worker arrives in the warehouses comes from Economic Scenarios .

This is a machine translation of a post published on Scenari Economici at the URL https://scenarieconomici.it/nei-magazzini-arriva-loperaio-robotico/ on Sun, 23 Jun 2024 09:00:09 +0000.